Scribblz Wall Drawing Robot

Project Overview

Scribblz is an autonomous wall-climbing robot designed to navigate vertical glass surfaces and create precise drawings based on user input. As the electrical lead on this team project, I was responsible for designing the custom PCB, power management system, sensor integration, and ensuring reliable electrical performance for all subsystems.

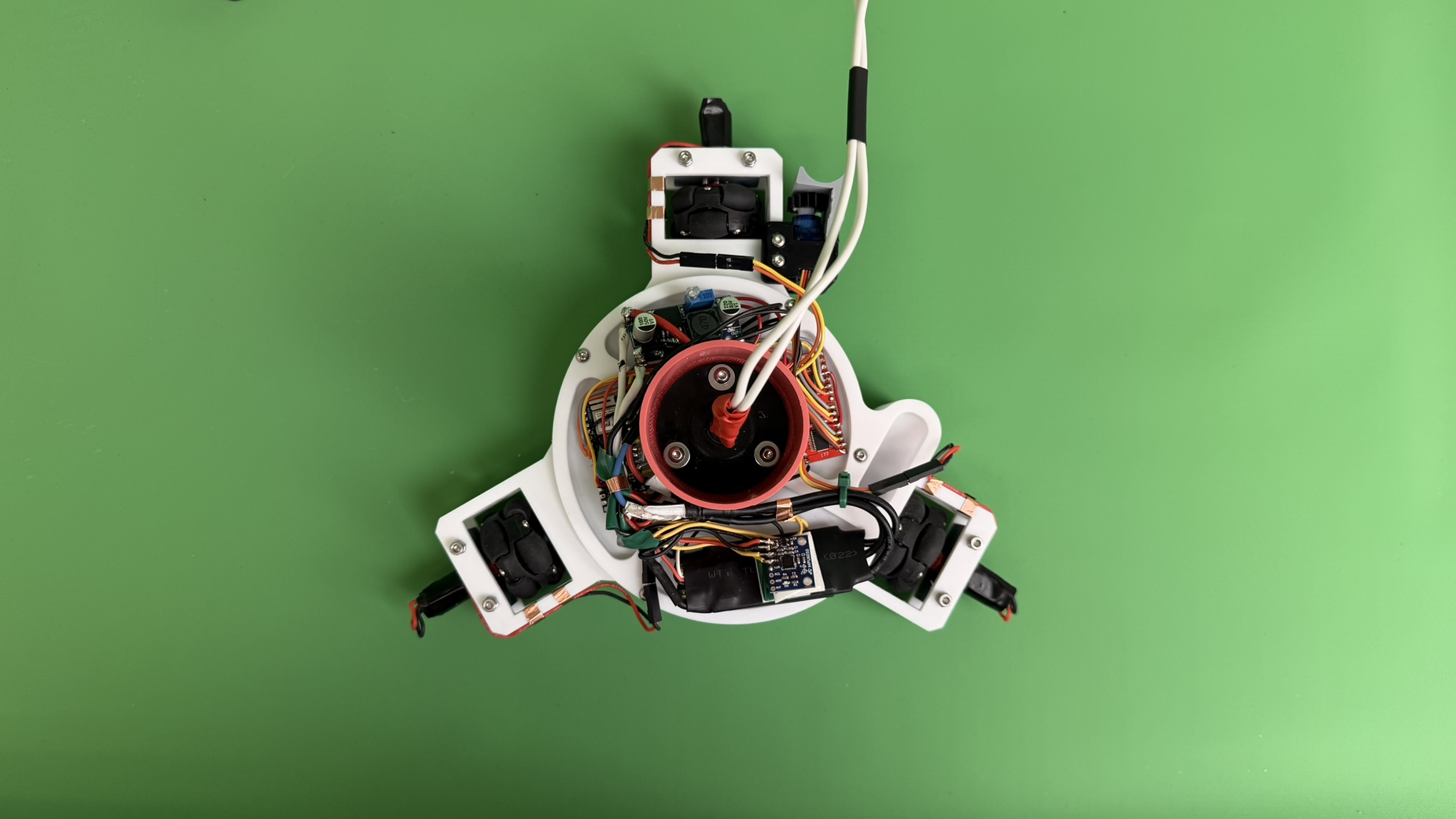

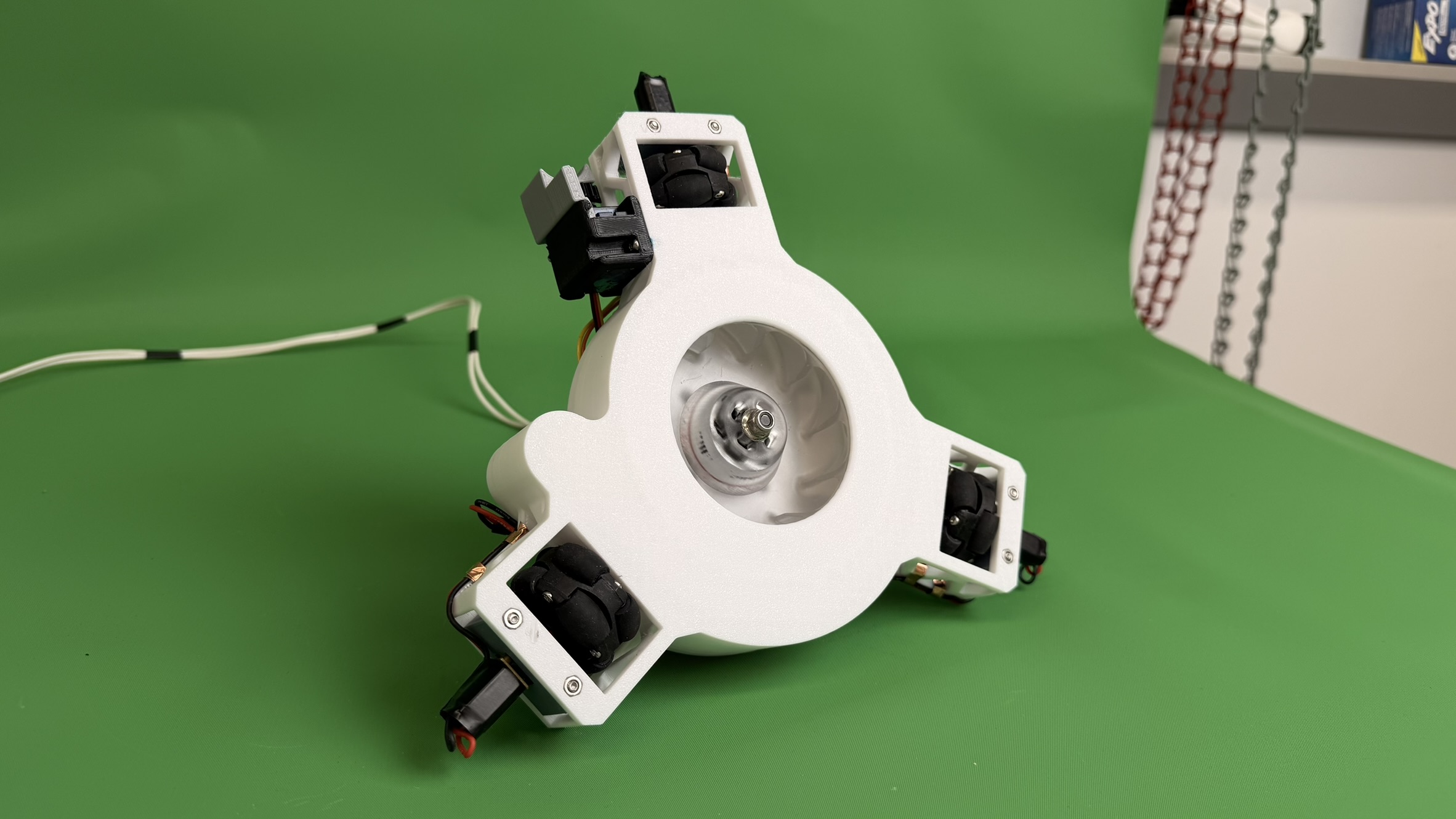

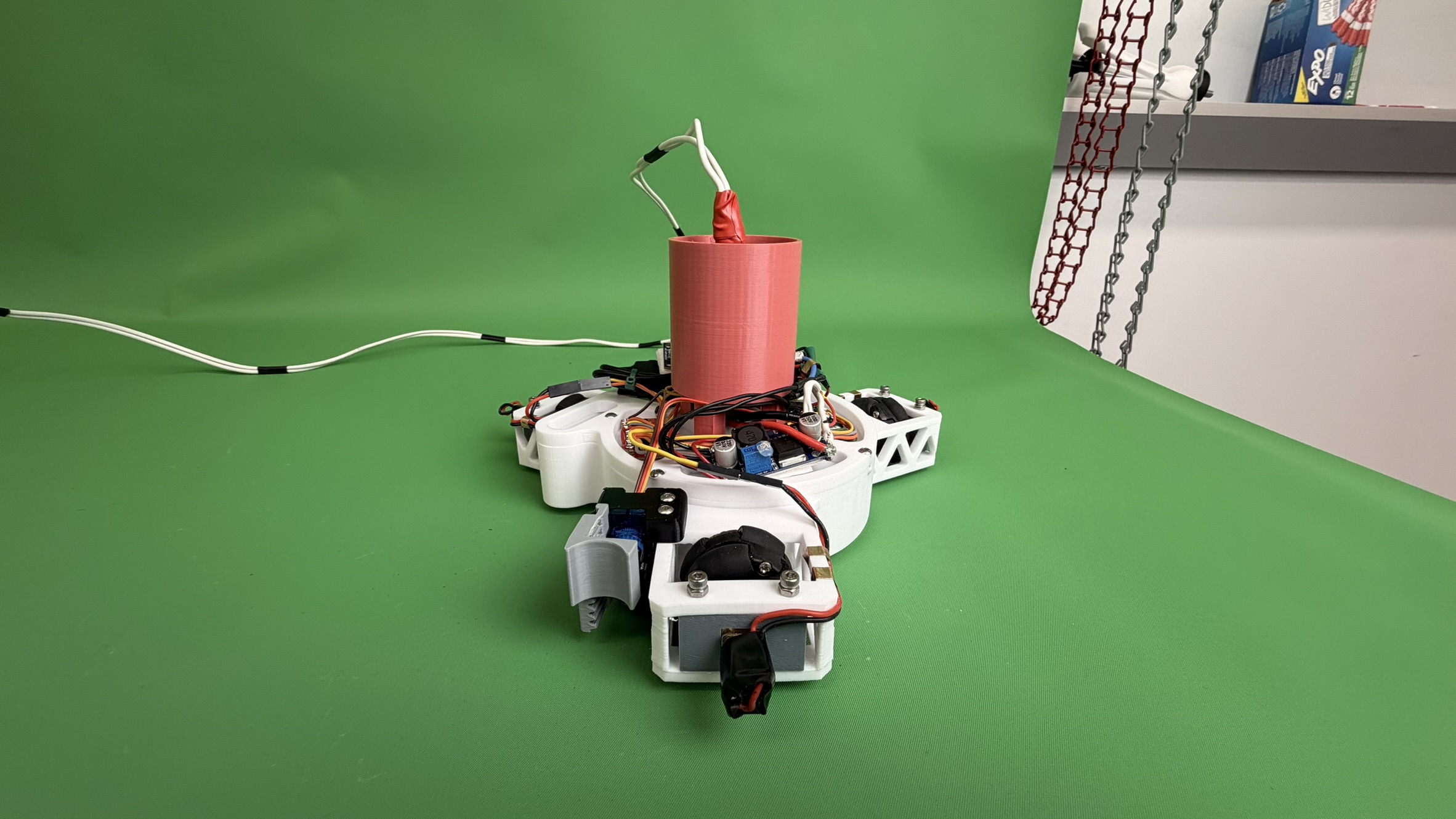

The robot features a high-powered custom impeller for suction-based adhesion, an omni-wheel drivetrain for holonomic motion, a servo-operated marker lift mechanism, and computer vision-guided auto-docking capabilities. This project combined mechanical engineering, electrical design, and software development to create a unique and functional robotic system.

Our team was driven by three main pillars: Purpose (giving wall-climbing robots a practical application), Novelty (creating something completely unique), and Longevity (designing for easy maintenance and future use).

The Challenge

Creating a robot that can reliably adhere to vertical glass surfaces while maintaining precise control for drawing requires careful integration of mechanical, electrical, and software systems. The electrical system needed to provide stable power to high-current motors, manage multiple sensors, and ensure fail-safe operation to prevent the robot from falling.

The Solution

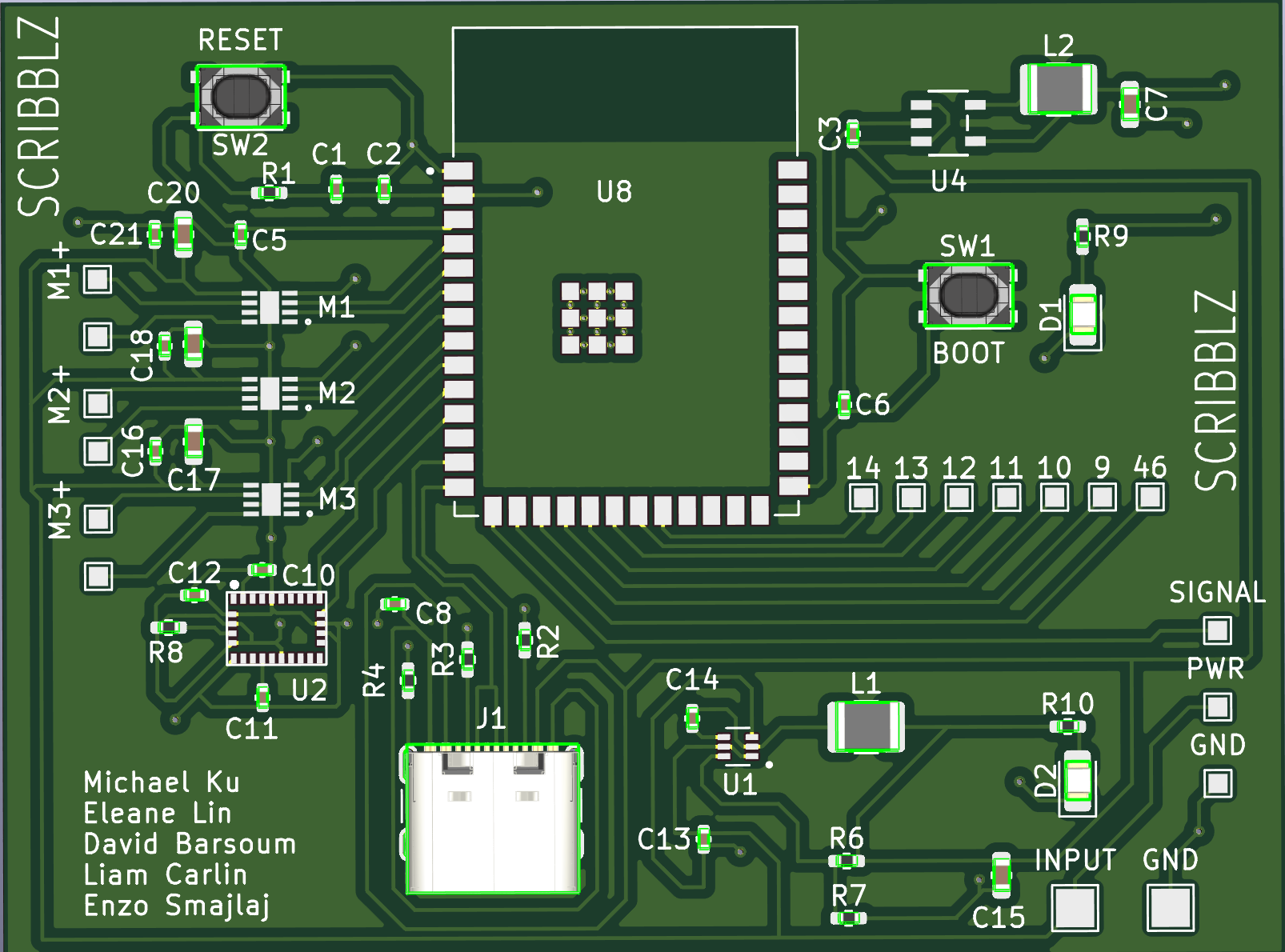

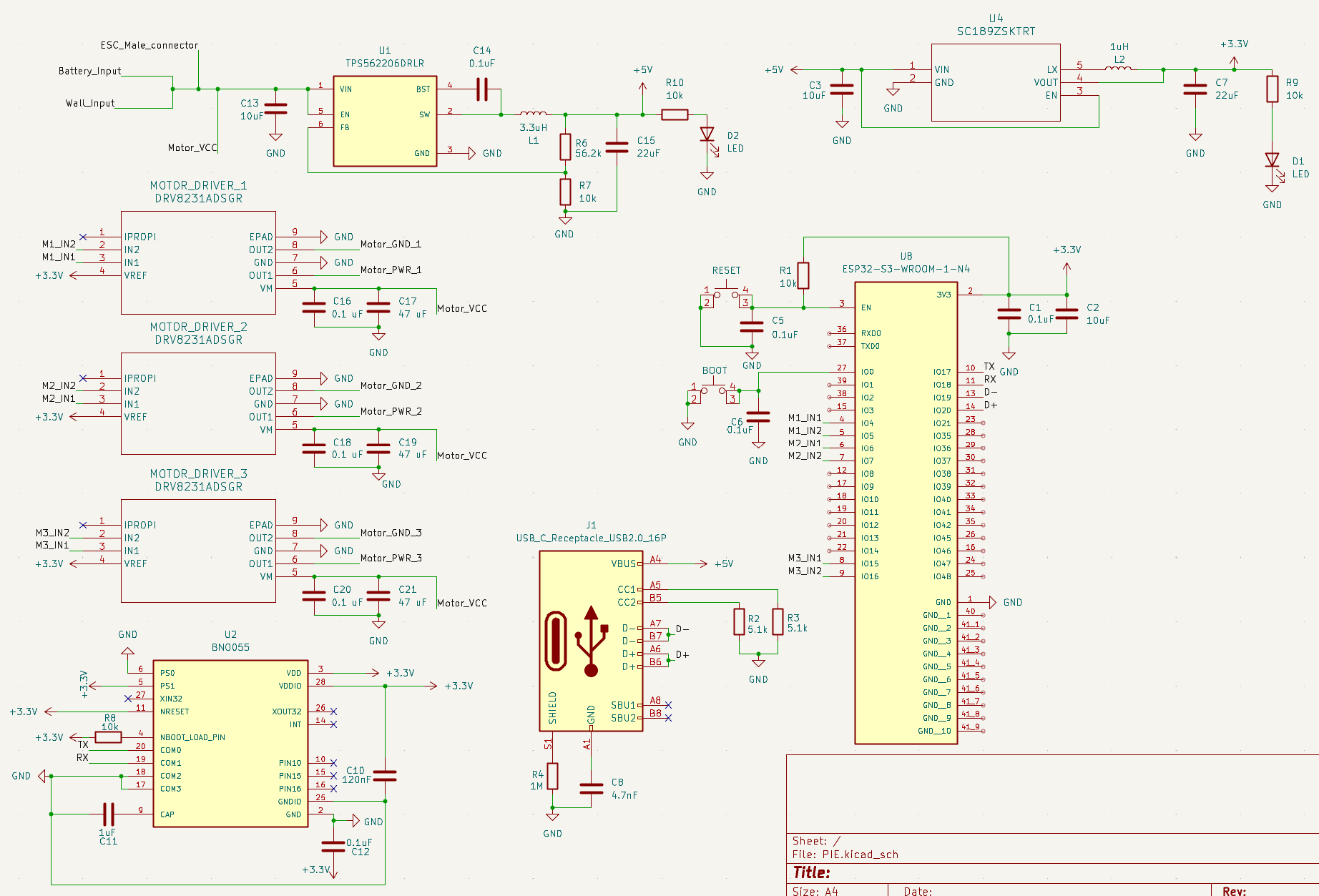

I designed a custom PCB with robust power distribution, integrated motor drivers, and sensor interfaces. The electrical system includes redundant safety features, efficient power management for the suction system, and clean signal routing for precise motor control. This foundation enabled the robot to operate reliably on vertical surfaces while executing complex drawing patterns.

Scribblz in Action

Watch Scribblz autonomously navigate a vertical glass surface and draw a smiley face

Project Gallery

Scribblz on vertical glass

Complete robot system

Bottom view - suction system

Side view assembly

Live schematic design

Original schematic

Technical Implementation

Electrical Design (My Focus)

- Custom PCB design and layout

- Power distribution system

- Motor driver integration

- Sensor interface circuits

- Safety and redundancy features

Mechanical Systems

- Custom impeller suction system

- Omni-wheel drivetrain

- Servo-operated marker lift

- Lightweight chassis design

- 3D printed custom parts

Software & Control

- Raspberry Pi main controller

- Computer vision for docking

- Path planning algorithms

- Wireless communication

- Drawing coordinate conversion

Key Features

- Autonomous wall navigation

- Precise drawing capabilities

- Auto-docking for charging

- Holonomic motion control

- Reliable glass adhesion

Key Learnings

This project significantly enhanced my skills in PCB design, power electronics, and system integration. I learned how to design for high-current applications, implement safety features for critical systems, and troubleshoot complex electrical issues in a multidisciplinary robotics project.

Working as part of a team taught me the importance of clear communication between electrical, mechanical, and software subsystems. I gained experience in collaborative design, where electrical decisions needed to account for mechanical constraints and software requirements.

The project also reinforced the value of thorough testing and iteration. Many of our electrical design decisions evolved through multiple prototypes as we discovered real-world challenges that weren't apparent in initial simulations.

Full Project Documentation

For complete technical details including CAD files, full electrical schematics, software architecture, system diagrams, and the bill of materials, visit our comprehensive project website: